Maltsters are in the inherent business of sprouting seeds; some might say…It’s the root of what we do. In theory, if we at Briess were to transfer the barley kernels from our germination beds to soil, and foster them in the right environment, we would simply get a new generation of barley plants. In fact, if you look at our modern agriculture and food systems, it’s the powerhouse of the seed that drives everyday life from the wheat flour in bread, oats in your granola, corn that provides feed for animal agriculture, and, of course, malt in your beer. It’s the maltster, however, that requires the seed to be living and perform its natural function to do our job.

Universally, many plant seeds have what is known as dormancy. Dormancy can be both a physical as well as a biological requirement that the seed needs to have met before it can induce germination. These factors are what ensure the seed, in its natural environment, does not sprout in unfavorable conditions. An example in the natural world is the hard coating of a tree seed (that water cannot penetrate), or a minimum cold period required before the seed can germinate; both are factors to why native plant seeds are able to delay sprouting until after winter. Barley is no exception when it comes to considerations about seed dormancy. While overcoming dormancy in barley can be a concern, in general, it can be the lack of dormancy that becomes a greater concern for the maltster and barley grower.

Photo credit: Nakamura, S. (2018). Grain dormancy genes responsible for preventing pre-harvest sprouting in barley and wheat. 68(3): 295–304.

Pre-harvest sprouting (PHS) is a phenomenon that can happen in barley prior to harvest, especially during wet years or untimely rainfalls while the grain is mature but not yet harvested. The barley will begin to germinate while on the barley head, essentially starting the malting process even before leaving the field. Many modern, high enzymatic barley varieties can have susceptibility to pre-harvest sprout. PHS-affected barley can cause several problems for the maltster, from increased water uptake, reduced uniformity in growth, and most critical, the viability of the malt. At the extreme, severely sprout-damaged barley will cease to germinate in the malthouse. On barley with severe pre-harvest sprout damage germination rates will continue to decline as storage time is extended. While problematic at higher levels, very minimal levels of PHS can be managed. The maltster can manage these negative effects by adjusting steeping regimes and scheduling PHS-affected grain to be first in the malthouse for the specific crop year.

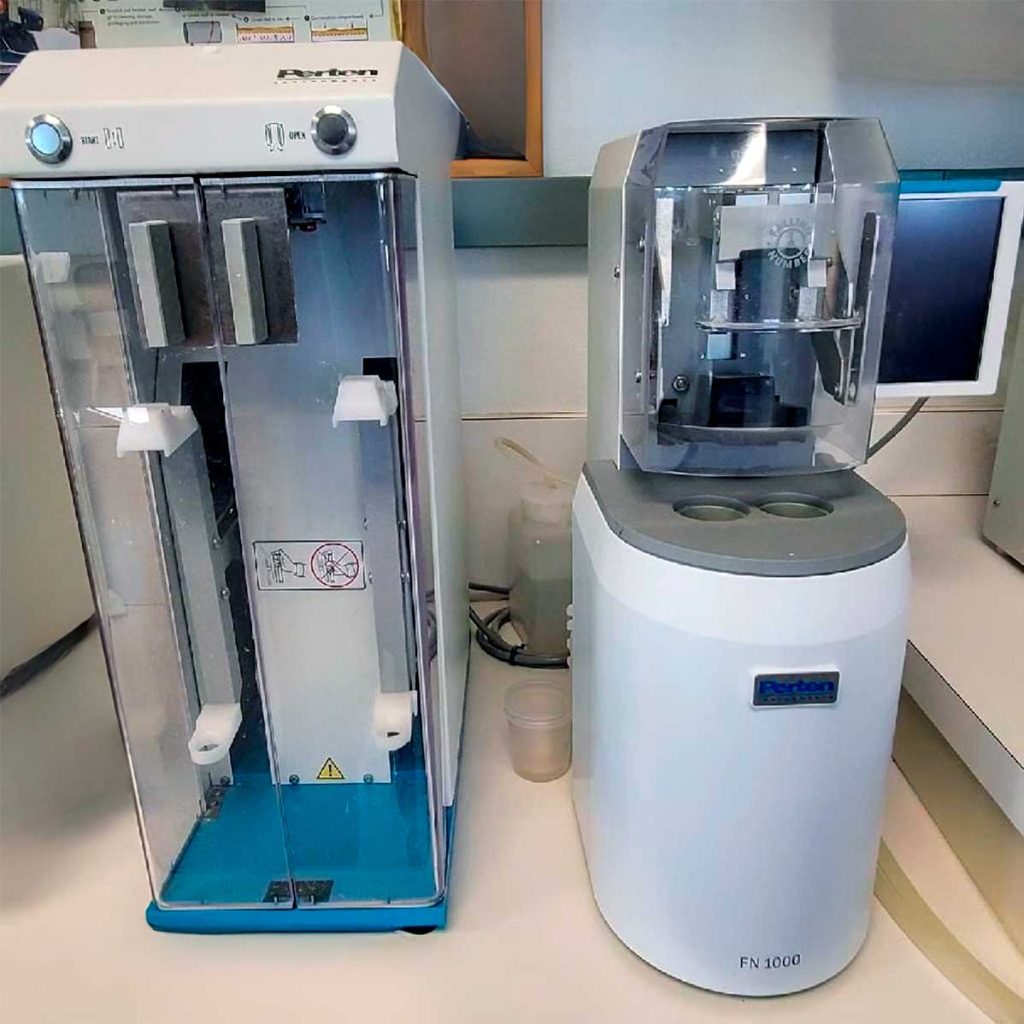

Like many maltsters, Briess has a maximum allowable sprout damage value to incoming grain. Briess grain operations and malting teams have a three-tiered approach in identifying PHS-affected barley, Sprout by Pearl, Falling Number (FN), and Rapid Visco Analyzer (RVA). Sprout by Pearl is a quick and simple first look at identifying if incoming loads of barley are sprout-damaged. This requires a grain pearler, which removes the husk of the barley kernel. In sprout-damaged grain, the embryo (living portion of the seed) will be removed from the rest of the kernel; non-PHS-affected kernels will keep their embryo intact. Although one of the quickest methods of identifying PHS, it does require subjective identification from a trained technician.

C. Pearled barley missing embryos (PHS damage).

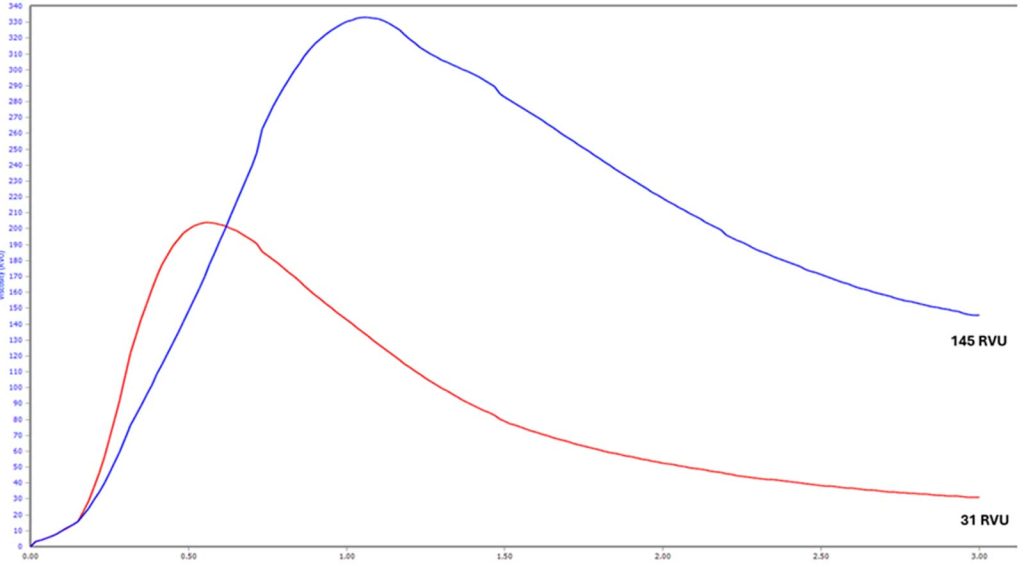

The Falling Number and Rapid Visco Analysis are very similar tests that identify if amylase is present in a barley sample, which is a key indicator of pre-harvest sprouting. Both FN and RVA units require the barley sample to be ground to a fine flour, with distilled water added, creating a slurry. In both test methods the slurry sample is heated to gelatinization temperatures, if there is amylase present due to sprouting, the enzyme will break down the gelatinized starch chains in the sample, reducing the sample viscosity. The falling number unit measures the viscosity of the sample by dropping a ‘plunger’ in the sample. The fall is timed and the less time the plunger takes to reach the bottom, the lower the falling number. Non-sprout-damaged barley is considered to have a falling number above 300.

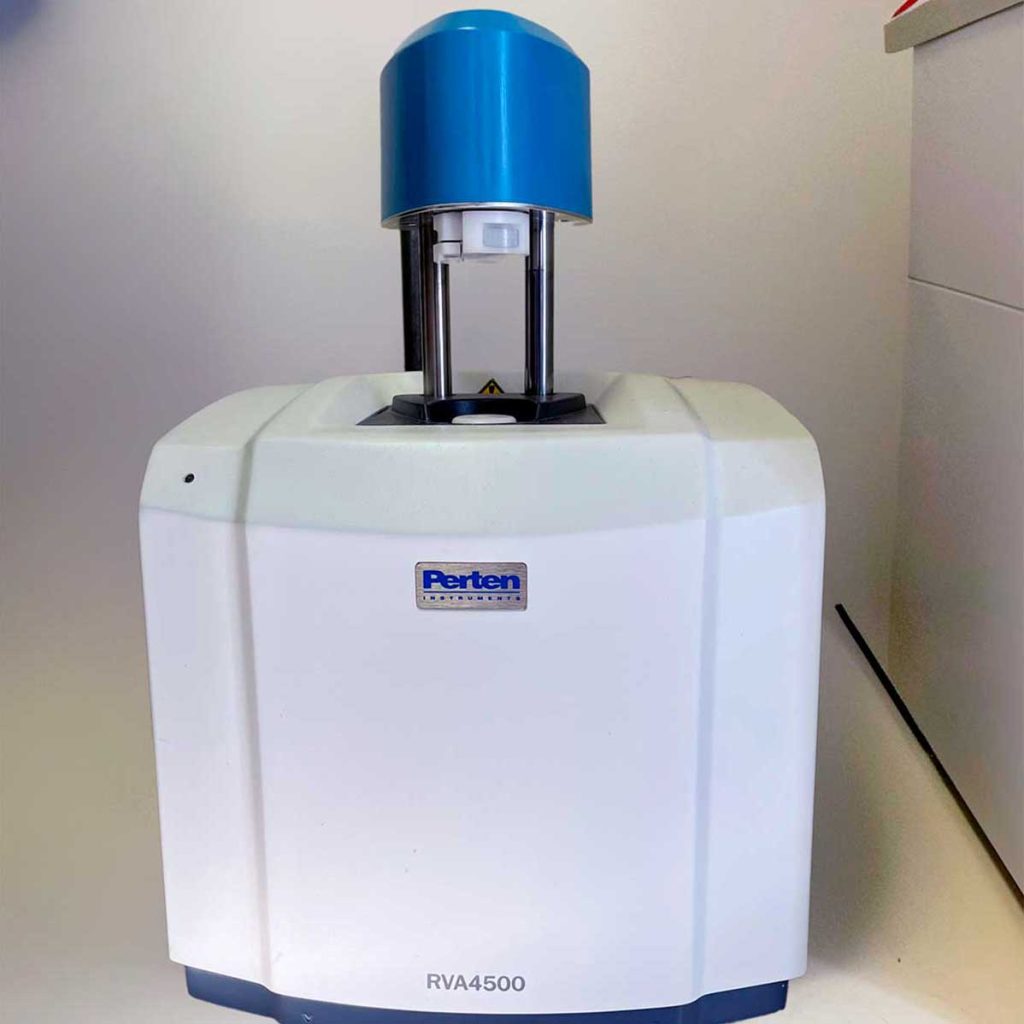

In the Rapid Visco Analyzer Stirring Number test the slurry is stirred with a rotating plastic paddle inside a heated metal can. The force against the paddle at a known speed can be calculated into a viscosity value and reported in centipoise (cP) or Rapid Visco Units (RVU). Barley samples that are below 1440 cP or 120 RVU are considered to have some degree of sprout damage, the lower the number, the higher the pre-harvest sprout.

Due to the specific nature of the tests, Briess utilizes both the Pearling and Falling Number tests for acceptance of incoming barley loads. Our RVA unit has the flexibility of multiple different uses for the Briess technical and quality teams and is utilized to validate and supplement testing for pre-harvest sprout. Pre-harvest Sprouting is just one of many barley quality considerations our teams are focused on to make the best possible malt here at Briess.